Metalock

About us

Metalock Venezuela is a leading company in on-site engineering repairs for all industries within the Caribbean area. Established in 1969, we have decades of experience in mechanical equipment repairs, with the capacity to offer immediate mobilization of our specialized technicians to fulfill all your in situ repair requirements.

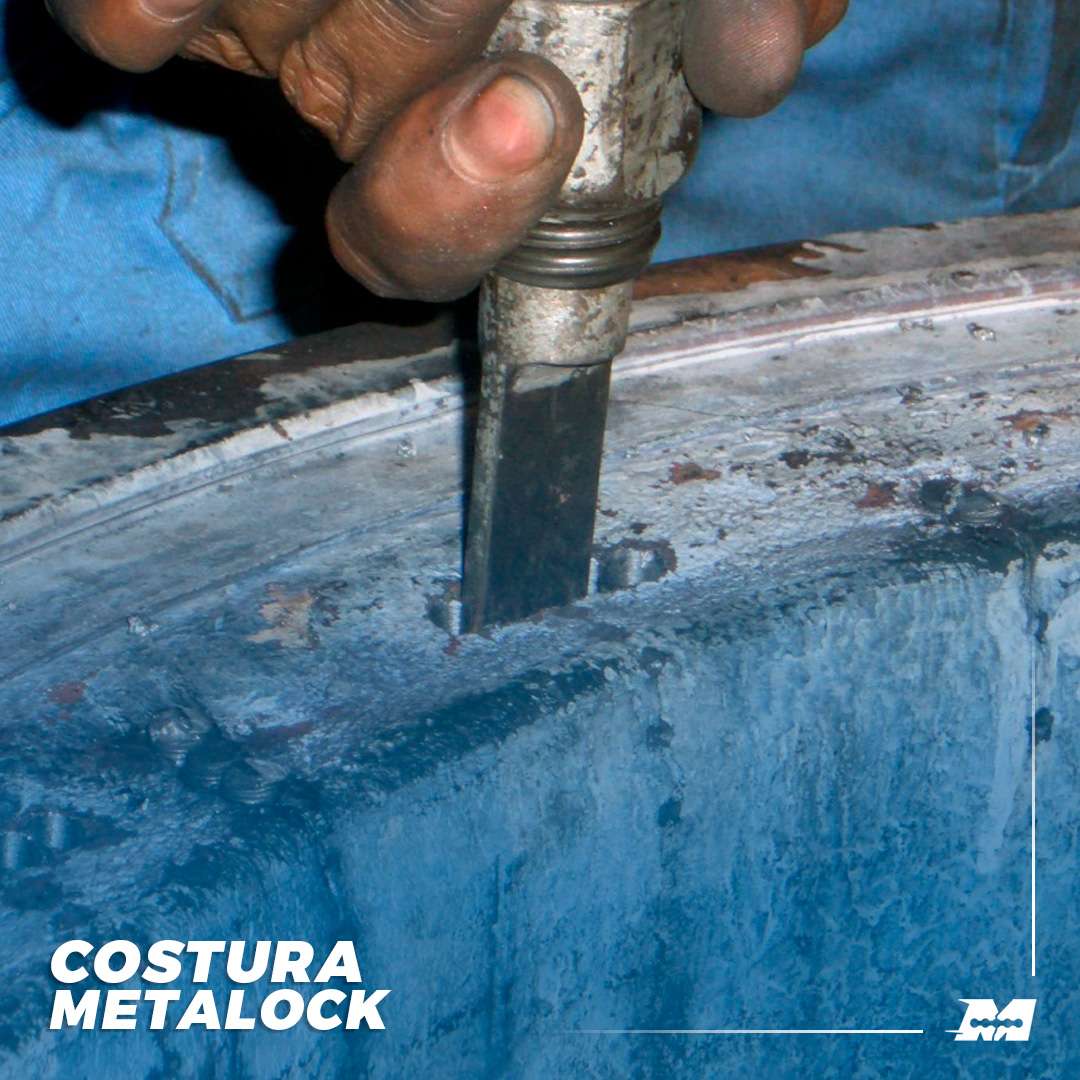

Our main service, “The METALOCK® Process”, is the only efficient way to join two pieces of metal through a successful and precise stitching and metal integration process to repair, in cold, damaged machinery parts with cracks, fractures or shattered parts.

Our primary services are

Metal

Stitching

It constitutes the only efficient way to join two pieces of metal through a successful and precise process of sewing and metallic integration to repair, in cold, damaged machinery parts with cracks, fractures or blasting.

Thermo-spraying

Recovery of damaged or worn parts to bring it back to its original specifications, with high-speed metal projection.

On-Site

Machining

This is machining, cutting, drilling, grinding, or polishing at the location of the equipment.

know the metalock

PROCESS

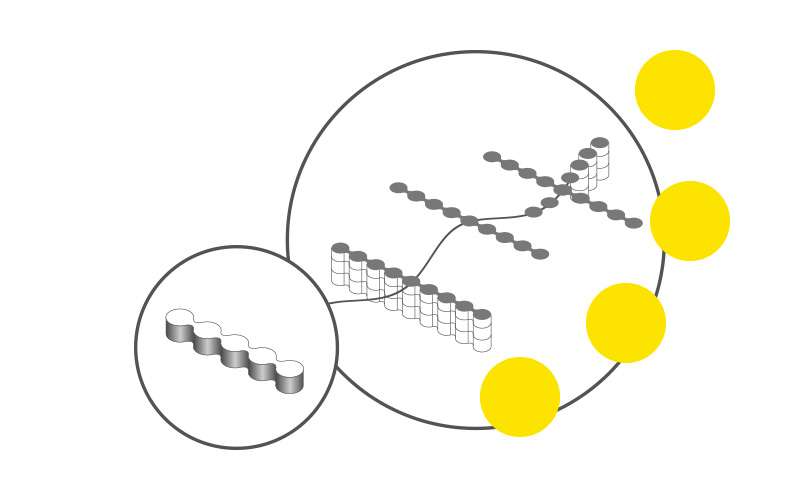

Casting Repair Process

The Metalock process, known as metal stitching, is a unique rapid and permanent method for repairing cracks or for joining pieces of broken cast metal components without welding.

Cold casting repairs carried out by Metalock International Association (MIA) members are superior to welding in the case of crack-sensitive metal. The repairs can take place in otherwise hazardous conditions for welding and cause minimal disruption to operations.

Each repair only requires equipment that can be carried by hand and is generally completed in a matter of days and can typically restore the strength of the equipment so that it will continue to operate to full specifications.

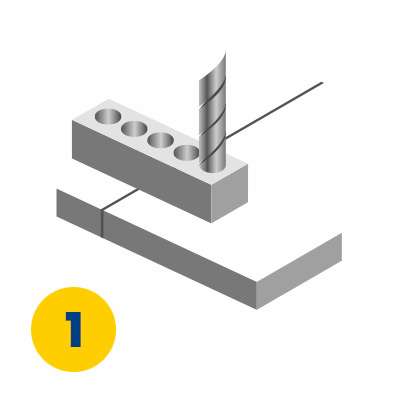

Casting Repair Process

The Metalock process is based on sound engineering principles accepted for over 70 years.

Drill holes along the fracture line, tap and fill with bolts.

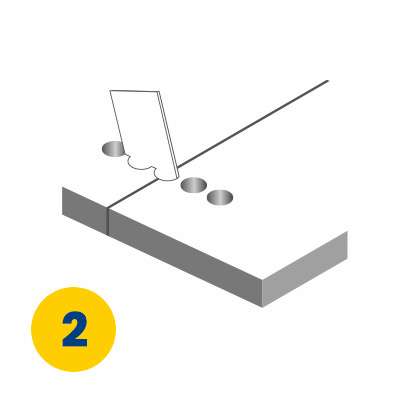

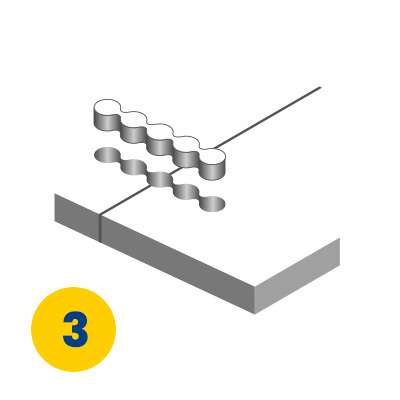

Drill holes at right angles to the fracture line.

Drilling holes in the shape of Metalock keys.

Layers of riveted keys in contact conditions between metals.

Using a drill jig, drill knockouts perpendicular to the direction of the crack. Each Row acts as a key.

Intermediate splits will be removed with a pneumatic chisel.

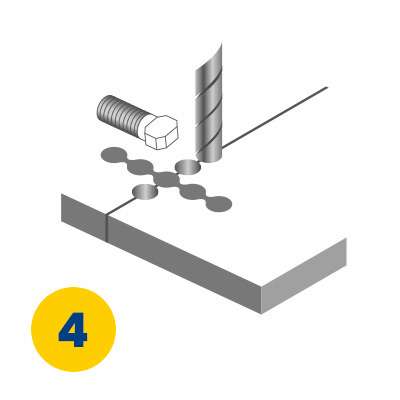

The openings made are sealed with METALOCK® keys.

Holes for METALOCK® screws are drilled along the cracks between the keys.

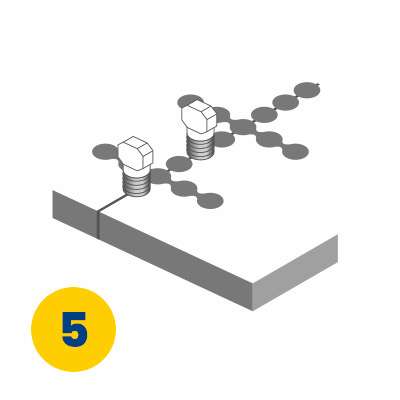

METALOCK® screws are placed, ensuring the seal throughout the fracture.

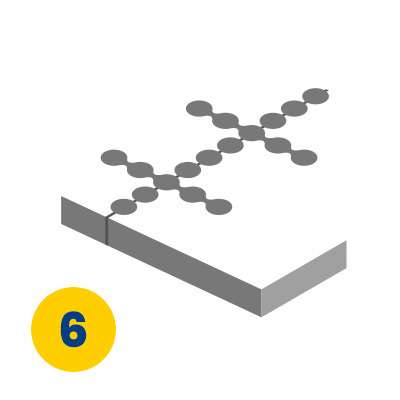

Finally, the installation is covered and sealed to guarantee stability, pressure adjustment and airtightness.

- Dampens and absorbs compression stresses.

- Provides a good ‘expansion joint’ for castings such as cylinder liners, cylinder head or any casings subject to thermal stress.

- Distributes the tension load away from fatigue points.

- Maintains relieved conditions of inherent internal stress where rupture occurred.

- Maintains alignment and original surfaces, since lack of heat produces no distortion.

- The vast majority of repairs can be done in situ, with consequent savings in time, with little or no dismantling.

- A pressure tight seal can be achieved due to the interlocking between Metalock keys and studding.

- Can be performed in-situ, thus major dismantling is not required.

- Produces permanent repairs that can be completed in days.

- Does not require hot work, so can be performed in any area.

- Can be used to repair cast iron and other metals.

- Cost is almost always less than replacement

Is accessible via a worldwide network of especially trained Metalock technicians, through the Metalock International Association. - Does not require heavy machinery or equipment to carry out repairs.

- Causes minimal disruption.

- Reduces downtime.

- Engine blocks.

- Cylinder heads.

- Gearboxes.

- Crankcases.

- Liners.

- Cylinder covers.

- Entablatures.

- Bedplates.

- Housings.

- Fly wheels.

know our

SERVICES

Since

1970

At the service of the Venezuelan industry

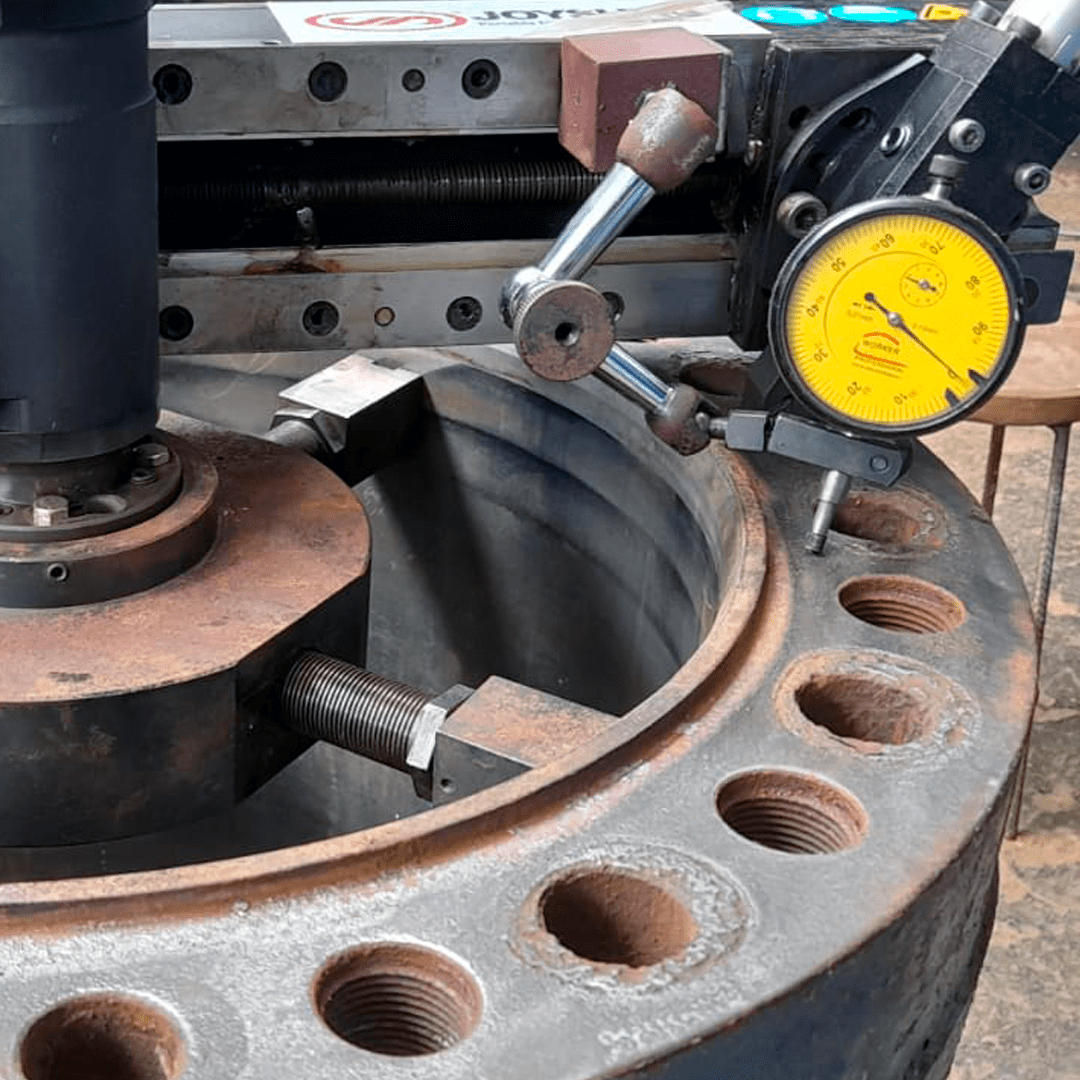

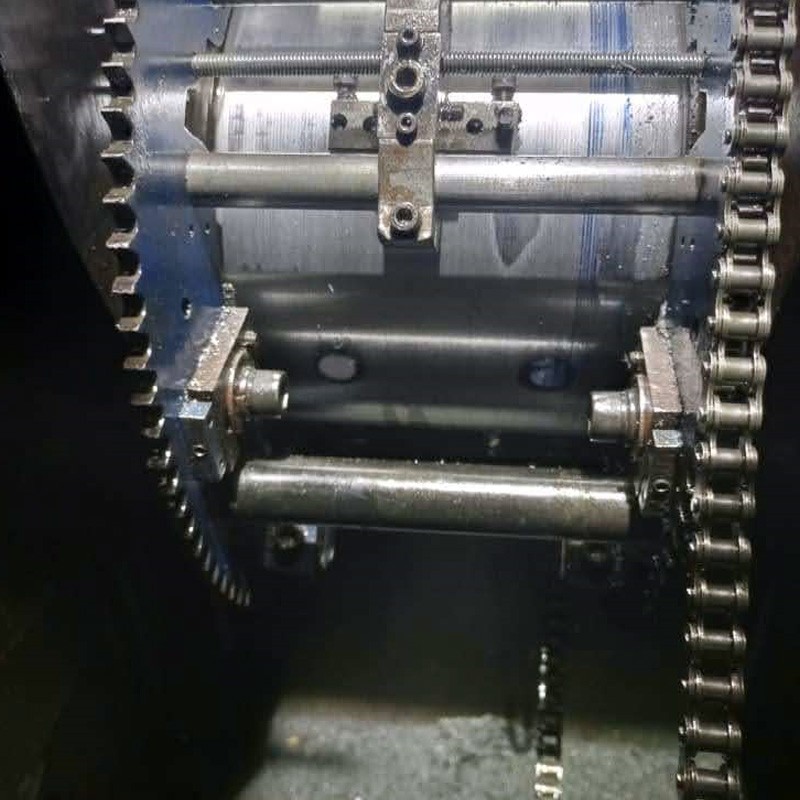

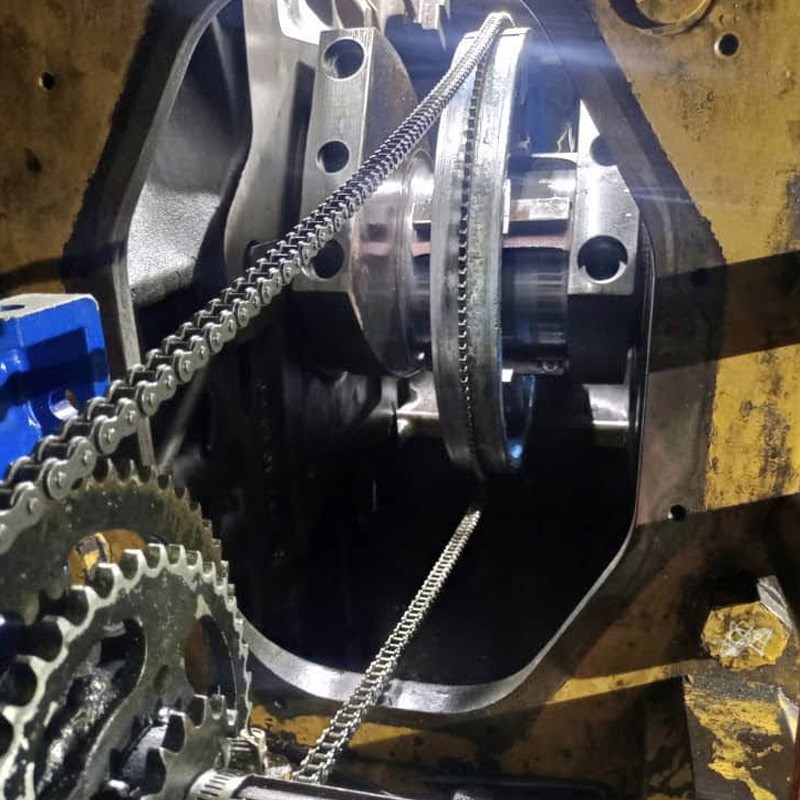

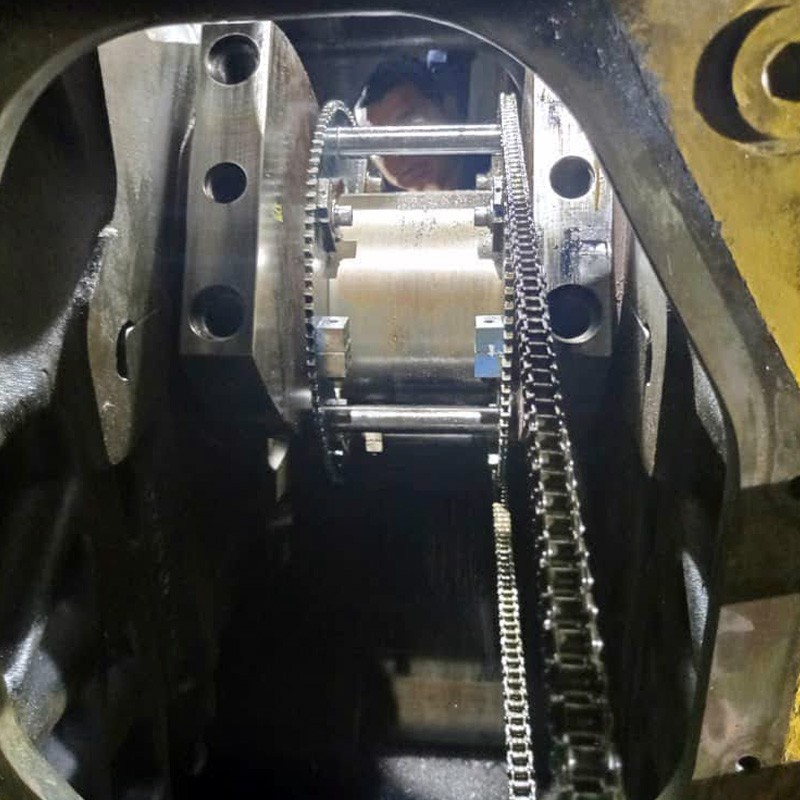

We have at our disposal the necessary equipment and technicians to be able to offer on – site machining solutions for crankpins, main bearing journals, flanges amongst others.

No matter what your machining requirements, we can provide the necessary support to meet your objective as soon as possible, avoiding costly downtime. . We have a team of specialists who, once your requirements have been evaluated, design and customize solutions.

METHODS OF MACHINING ON SITE

• Line boring.

• Orbital machining.

• Machining of flanges.

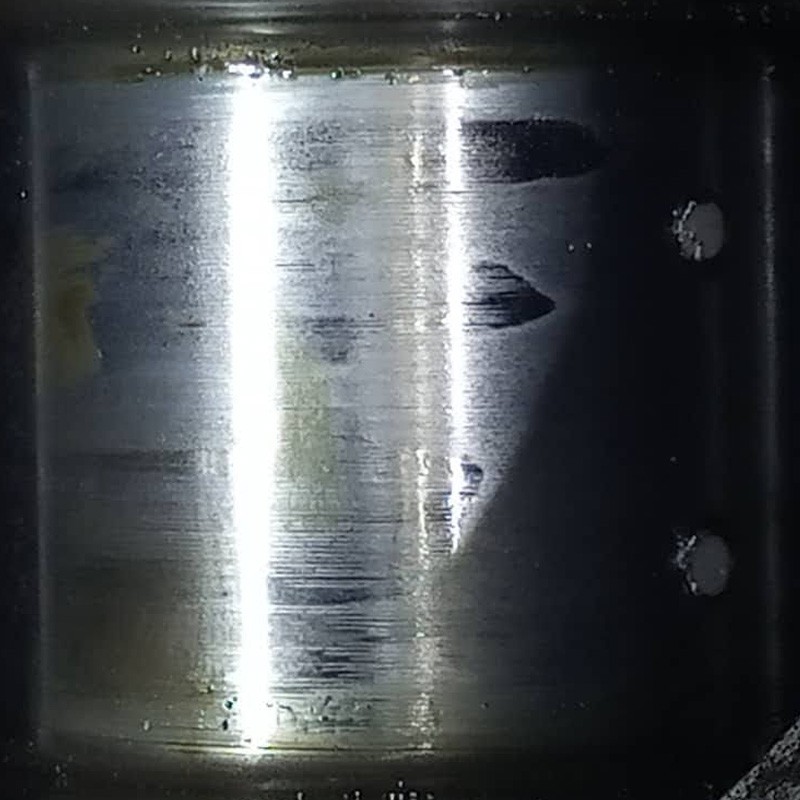

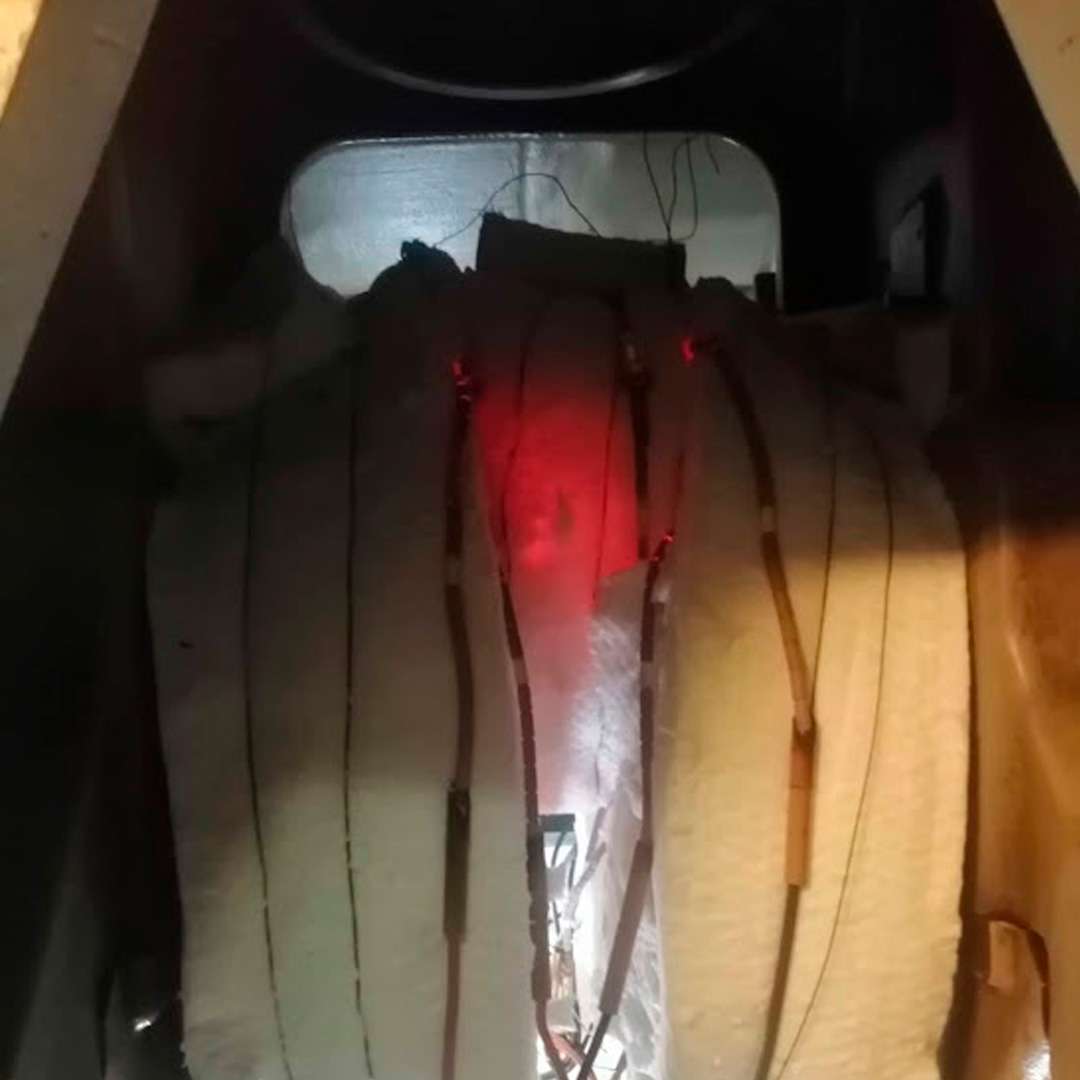

Thermo-spraying is a high-tech process for the creation of functional surface coatings with specific material for different requirements.

It consists of spraying a metallic or non-metallic melted material, with high speed on the surface to be recovered, thus resizing it to its original dimensions or protecting it against the environment, as the case may be.

Through this process we recover vital pieces of industrial machinery, damaged or worn, surpassing in many cases the original standards of the manufactured piece.

This process is described as the projection of molten material particles against a base material. These particles are fired at speeds higher than sound and embedded in the substrate and between them, thus forming a dense coating, strongly adhered to the base material and with a hardness generally greater than the base material itself.

Resistance to wear by abrasion, cavitation and/or erosion

Resistance to corrosion by aggressive agents, such as: acids, sulfur gases and solvents

Dimensional recovery: Recovers original dimensions, where the coating will have the same or better characteristics than the original coating

It is a low temperature process that does not exceed 200° C during the deposition of the coating, thus eliminating deformations and changes in the microstructure of the base material, extremely dangerous for the physical integrity of the piece.

The materials used in thermo-spraying can be applied on surfaces that cannot be welded, either because of their composition or very thin thicknesses.

Our laser alignment service, which can be carried out on site, reduces the expense and time required to perform precision inspections up to half a thousandth of an inch (0.0005 “) tolerance.

Alignment of rotating equipment with laser precision including turbines, motors, chains, belts, shafts, amongst others.

Pre-machining survey.

Alignment of shafts and bearings.

On-site dynamic balancing of rotors.

We have a team prepared to drill and extract broken studs on site.

- MIG Type welding.

- TIG welding.

- Welding with electrodes.

- Casing repair.

- Internal coating by ceramic tiles.

- Application of epoxy and polymeric products.

- Hydrostatic test.

- Refurbishment of vacuum pumps.

- Reconditioning of horizontal spiral centrifugal pumps.

- Reconditioning of vertical suction pumps.

- Bipartite horizontal pump reconditioning.

MARINE AND

OFFSHORE

General Mechanical Services

Reconditioning and maintenance:

- Pumps.

- Valves.

- Cylinder liners and heads.

- Air Compressors.

- Pipes.

Fabrication of Parts

- With our network of machine shops in the Caribbean region we can meet all of your requirements with high quality and speedy service.

Metalock Stitching

- Our exclusive Metalock Process can be applied to:

- Engine Blocks

- Cylinder Liners

- Cylinder Heads

- Fly wheel

- Bedplate

- Gearbox housings

Diesel Main Engine, Auxiliary Engines and Turbines

- Overhaul and Maintenance

- Component reconditioning

- Stud Removal and renewal of threads

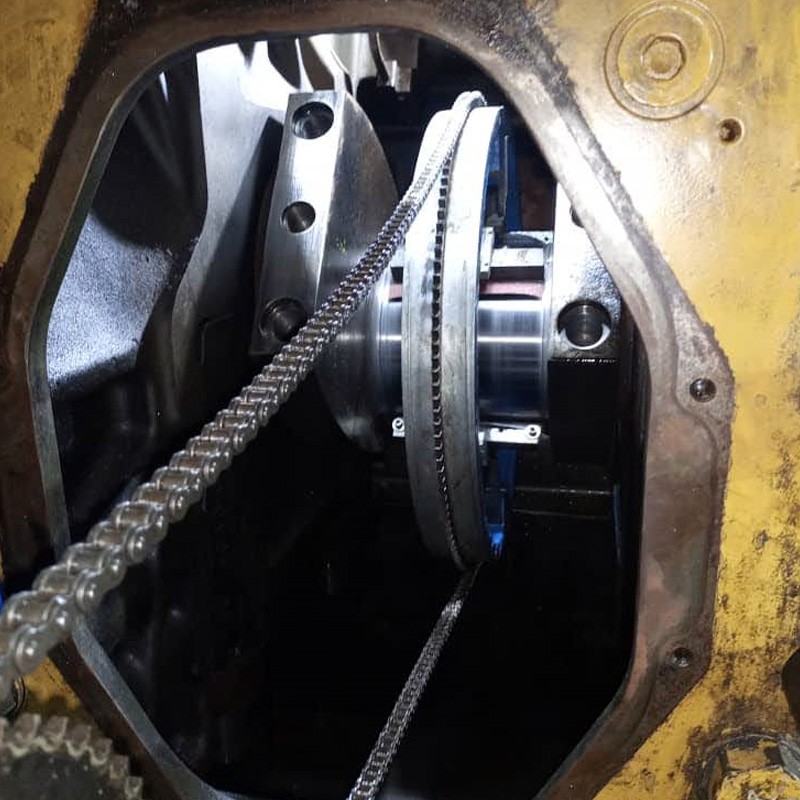

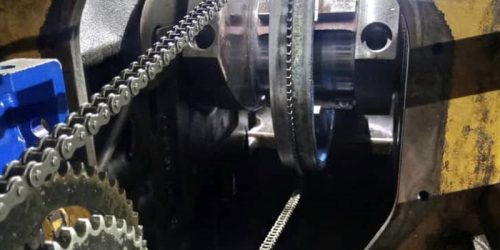

In-Situ Crankpin and Main Journal Repairs

- Repair worn or damaged crankpins and main journals

- Machining and polishing are carried out to OEM standard

- No dismantling required

- Downtime and costs reduced

- Immediate response

Laser and Optical Alignment

- Propulsion Shafts.

- Engine Mountings.

- Engine Blocks.

Crane Repair

- Repair and Maintenance.

- Electrical and hydraulic.

Welding and Plate work

- Certified welders for all your requirements.

- Hull work also reinforcements.

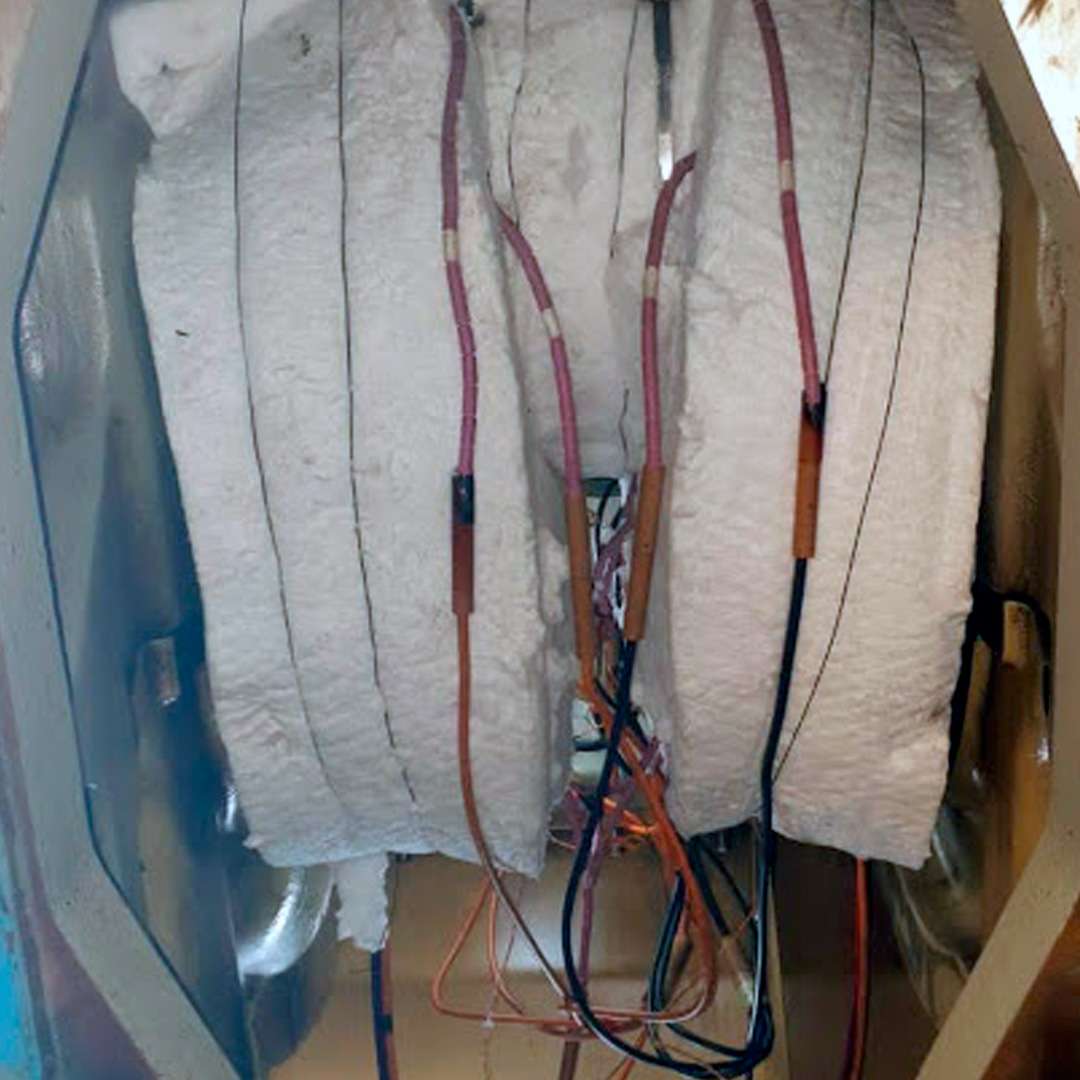

OUR

JOBS

Certificates and accreditations

location and

Contact

Main Office

Local 37-24 Las Minas de Baruta, Caracas, Edo Miranda Código Postal 1080, Venezuela.

Phones: +58-212-944.64.43 / 944.71.53 / 944.42.30

E-mail: [email protected]

Anaco Workshop

Avenida Zulia N° 6-44, Anaco,

Edo. Anzoátegui

Teléfonos:

+58 282-422.20.15/422.24.68/ +58 412-878.98.04

Puerto Cabello Workshop

Calle Municipal N° 3-74,

Puerto Cabello, Edo Carabobo

Teléfono:

+58 412-413.21.96

WHATSAPP | EMERGENCY

+584241422319

We are the exclusive representatives of the Metalock International Association for the following countries:

REPÚBLICA DOMINICANA

SURINAM

GUAYANA FRANCESA

HAITÍ

ISLAS VÍRGENES

CURAZAO

ARUBA

TRINIDAD Y TOBAGO

JAMAICA

BAHAMAS

BONAIRE

RESTO DEL CARIBE